The History of Bendix-Stromberg Carburetors and Their Application To WWII Aircraft

First, I have to clarify that I am no expert when it comes to carburetors or engines in general, but I love history and realize how influential breakthroughs like the floatless carburetor were in the victory of WWII. I know there are a lot of experts out there who know far more than me, so make sure to share anything I missed or errors I have in the comments below.

From my understanding and research, float-type carburetors worked great until an aircraft flew upside down, endured negative g-force, or flew at high altitudes, which are all techniques in combat. In the beginning of the war, the RAF knew this problem best and far too well. Spitfires could hold their own against the ME-108 until performing a barrel roll. In the middle of a roll, the engine would flood with fuel and the aircraft would eventually stall and blow black smoke - giving the Germans a better shot. A British woman engineer, Beatrice Shilling, came up with a temporary fix.

Click Here to watch a video for more detail about Spitfires flaw.

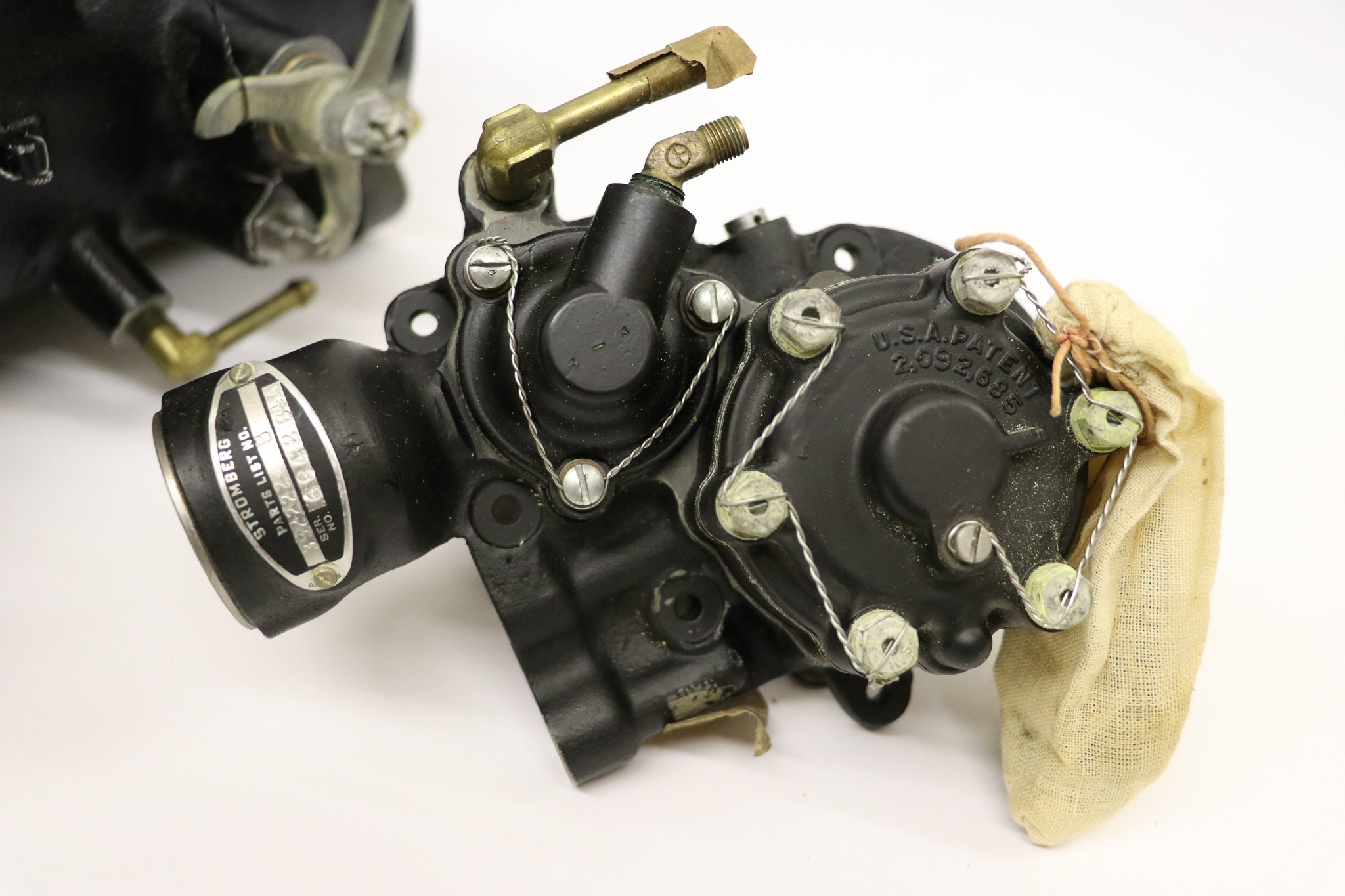

Meanwhile, Bendix Aviation Corporation set out to solve the problem long term, and they did, with the invention of the pressure carburetor. Bendix-Stromberg surpassed other manufacturers with the design and became the most commonly found carburetors on WWII aircraft. They proved to have the best performance when it came to negative g-force and flying upside down. The first Bendix-Stromberg pressure carburetor, model PD12-B, was installed on an Allison V-1710-7, and eventually flown. The carburetors were used on both Pratt & Whitney and Rolls-Royce Engines.

The design of a Stromberg fuel injection carburetor consists of three main components: the throttle body, fuel control, and the fuel regulator. The throttle body was the main house and contained the venturis and throttles. The fuel control was made up of the jets and mixture control plates. Lastly, the fuel regulator, which contains the fuel and air diaphragms, metering valve and enrichment diaphragms and valve, makes the magic happen.

If you want to learn more about the design and application of the carburetors, I highly recommend checking out this article.

Over 496 different models of carburetors were made to fit over thousands of engines, for thousands of aircraft. With such demands to meet, came a need for serious organization. Bendix-Stromberg carburetor models each have different and specific designations depending on size, style, etc. For example, each model begins with two letters: PS, PD, PT, or PR followed by numbers that indict the size of the round bores.

We have over 150 carburetors in our inventory, six different models. Check them out and let us know if you need one! And please make sure to comment anything informational or helpful below in the comments!